The ballast water embarked on the ballast tanks allows the ships to maintain good trim, propeller immersion, and sufficient stability to proceed safely on a ballast voyage.

The problem of ballast water is that billions of water, including species of plants, bacteria, and other marine organisms, are transported during the ballast voyage.

The marine organisms transported into the ballast water may negatively affect the country’s territorial waters, where that particular organism may not yet exist.

Page Contents

BALLAST WATER MANAGEMENT CONVENTION

The IMO adopted the international convention to control and manage ships ballast water and sediments in February 2004.

This convention’s main scope is to ensure that maritime nations respect and take measures to prevent and reduce the transportation of harmful marine organisms by appropriate management of ships ‘ballast water and sediments.

The measures include rules for the design, control, and construction of:

- Methods and systems for ballast water exchange

- Sediment control on ships and port reception facilities for sediments when ship’s ballast tanks are cleaned or repaired

- Designated areas for ballast water exchange

- Port reception facilities for receiving ballast water and sediments.

Besides, on the ballast water management convention, we found:

- The use of ballast water sampling

- A ballast water management system

- Use of risk assessment methodology for ballast water management

- Ballast water treatment methods and techniques including the design and approval of the systems and equipment used

Ballast water exchange methods

Any method used to exchange ballast water should prevent the transfer of marine life from a country to another.

Following the exchange methods:

Sequential or empty / refill exchange ballast water

This involves exchanging ballast water in ship’s tanks with seawater by emptying and refilling them in sequence or individually with water from oceans.

By some studies, the seawater organisms loaded in coastal areas do not survive in the open sea due to differences in the environmental conditions.

This method ensures a nearly complete exchange of ballast water in ship’s tanks; it may not remove sediments.

The ship’s officer, while performing this type of ballast water exchange methods have to keep in mind the following factors:

- Whether the objective of removing marine organisms is fully achieved

- An assessment of the sediments that may remain within ballast tanks

- The effect of emptying tanks will have on the stability of the vessel

- The impact of emptying tanks will have on the strength of the ship,

- The time that may be required to complete the operation

Pump-Trough exchange (overflow method)

In this method, the ballast water in the ship’s tanks is diluted by adding more water during the voyage at several positions.

Since the tanks are not emptied, changes in the vessel’s stability or stress are not an issue.

However, to obtain a complete exchange of the ballast water, the equivalent of at least three times the amount in each tank has to be pumped.

Ballast treatment

Mechanical treatment

Many marine organisms can be filtered out of ballast water by specialized filtration plants; due to the large quantities of ballast water required, the process is either very slow or need a large capacity filtration plant.

Additionally some micro-organisms may still escape through the filters.

Chemical treatment

Chemicals are known as biocides, either oxidizing agents ( chlorine, ozone gas) or non-oxidizing agents are used to killing marine organisms.

While this effectively treats ballast water, the chemicals should be handled carefully to avoid personal injury.

Physical treatment

The physical treatment of ballast water may be by ultraviolet, ultrasound, or thermal energy ( maintaining ballast water temperature between 34-45 ) to destroy marine life within ballast water.

The main limitation of this method is that ships need to be fitted with additional equipment and pipelines.

It means an increase in initial costs as well as the running cost.

Control of ballast water

In some ports, ships may be able to lead clean ballast water from storage tanks.

This water may be recycled or treated.

Some optional are also to provide clean ballast to ships by a certified company, but this method can give some disarranges

Equipping ships with suitable systems to receive ballast

Cost of ballasting operations to the ship from possible increases in port stays in addition to the extra port

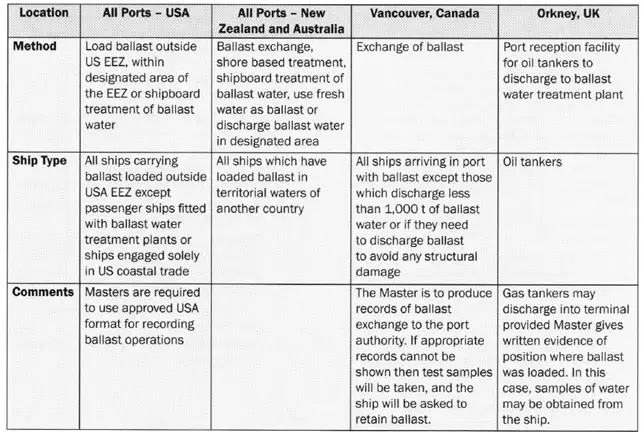

Ballast water exchange requirements

There are two standards in the ballast water convention for the exchange of ballast water.

Ballast water exchange standard

Ballast water exchange must have an efficiency of 95% volumetric exchange.

By the pumping-thought method, a volume of water equivalent to three times each ballast tank is considered sufficient.

Ballast water performance standard:

Ships are required to discharge:

- Less than 10 viable organisms ( dimension greater than or equal to 50 micrometers) per cubic meter of ballast water

- Less than 10 viable organisms ( dimension 10-50 micrometers) per millimeter of ballast water

Ships are allowed to comply with standards other than the ballast water performance or exchange requirements provided that they meet the same level of environmental protection set by the IMO.

The ballast exchange should:

- Be done at least 200 nautical miles from the nearest land in the water of at least 200m depth.

- Where the above condition cannot be met at all, then at least 50 nautical miles from the nearest land in the water of at least 200m depth

- If both above conditions cannot be met, then exchange must take place in areas designated for ballast exchange by concerned states

- In all cases, dispose of ballast water sediments as stated in an approved ballast water management plan

- Comly with additional national requirements to control the transfer of organisms through ballast water exchange.

BALLAST WATER MANAGEMENT SYSTEM

The ballast water management systems aim to prevent the transportation of marine organisms into foreign seas in ships ‘ballast water.

Ships are required to have

- An approved ballast water management plan

- A ballast water management certificate

Every ship is required to have a specific BWM plan, in the working language of the shipboard personnel and either English, French or Spanish, and must be approved by the administration, incorporating the following:

- Procedures for the safe management of ballast water

- Description of the shipboard implementation of the ballast water management plan.

- Details of techniques to dispose of sediments at sea, port, or drydock

- Procedures for coordination between the ship and harbor/ port authorities required to manage ballast water operations.

- Ensuring that a ship’s officer is in charge of implementing the BWM plan.

- Requirements for ships to report operations or incidents involving ballast water.

A BMW must comply with the IMO’s marine environmental protection Committee (MEPC), the international association of independent tanker Owner (INTERTANKO), and the ICS.

According to the BMW Convention, states may establish ‘concerted area’ in the same way as a special area for MARPOL.

BALLAST WATER CERTIFICATE AND INSPECTION

When the BMW convention is implemented, ships will be issued with the ballast water management certificate with a validity of 5 years.

The port state control inspectors may inspect the BMW certificate and ballast water record book, check samples of ballast waters to verify compliance with exchange requirements.

What happens if there is some suspect on ballast water?

The psc inspectors suspect that Bwm requirements are not being complied with, a detailed inspection may be called for.

Ballast water record book

Under the Ballast water management convention regulation B-2, ships must have a Ballast Water record book detailing the vessel and including diagrams of the ballast water tanks.

What do you write in the ballast record book?

- Loading ballast water:

Date,time, position / location of vessel

The volume of ballast water

Signature of an officer in charge.

- Discharging ballast water to the sea, as above, and:

The volume of ballast water remaining onboard after partial discharge.

- Discharging ballast water to port reception facilities, all entries as in 1 and 2 above, in addition to the name of the port and whether or not the BWM has been complied with.

- Accidental discharge of ballast water:

All entreis as for 3 above, in addition to a statement describing the reasons for accidental discharge.

- All cases of ballast water treatment or circulation within the ship.

The ballast water record book should also comply with the following:

- Keep on board for at least two years from the last date of entry, after which it should be kept in the company’s control for at least three years.

- Detail any accidental discharge of ballast water

- Be available for inspection by port state control inspectors

- Details all operations involving ballast water, duly signed by an officer in charge of the operation.

Read: Climate change